Today, maximizing operational efficiency is critical for maintaining productivity, reducing costs, and ensuring consistent output. One of the most effective ways to achieve these goals is by integrating precision motion products. These advanced systems enable highly accurate movement control, essential for applications ranging from manufacturing and robotics to medical devices and aerospace.

Precision motion products, such as linear actuators, servo motors, and motion controllers, are designed to deliver exceptional accuracy, repeatability, and reliability. By minimizing errors and optimizing performance, these components can help industries streamline processes, reduce waste, and enhance overall productivity.

Read on to learn how motion products can improve operational efficiency and efficiency in industrial settings.

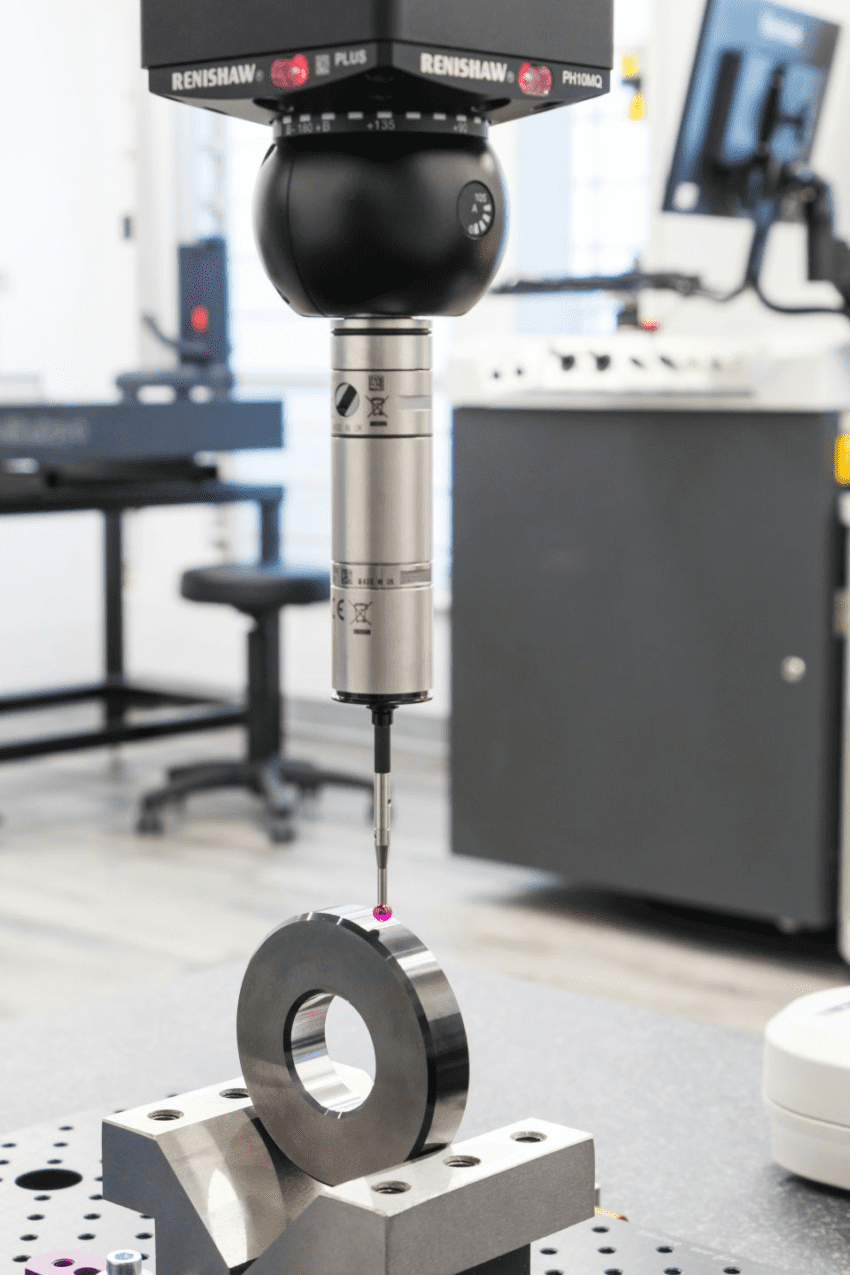

The Role of Precision Motion in Industrial Automation

Industrial automation relies heavily on precise motion control to execute complex tasks with minimal human intervention. Precision motion products can ensure that robotic arms, conveyor systems, and CNC machines operate with the following outcomes:

- Enhanced Repeatability: Precision components can guarantee that movements are consistently replicated, eliminating variations that can lead to defects.

- Reduced Downtime: High-quality motion systems are built for durability, minimizing maintenance requirements and unplanned stoppages.

- Improved Energy Efficiency: Advanced servo drives and controllers can optimize power consumption, lowering operational costs.

Given the role of precision motion products in industrial automation, consulting with reputable providers like Griffin Motion would be an excellent start. They specialize in providing high-quality motion solutions tailored to industrial needs, ensuring seamless integration and long-term performance.

Minimizing Waste and Rework

Even minor inaccuracies can lead to significant waste in industries where material costs are high. Precision motion products can help mitigate this by ensuring that cutting, welding, and assembly processes are executed with exact specifications. Here’s how these products can help:

Tighter Tolerances

Precision motion systems can ensure micron-level accuracy, critical for industries like aerospace, medical devices, and electronics manufacturing. By maintaining exact tolerances, these systems can minimize material waste, reduce defective parts, and enhance product consistency. This level of precision can directly translate to higher yields, lower production costs, and improved compliance with stringent industry standards, making operations more efficient and cost-effective.

Faster Adjustments

Advanced motion control systems incorporate real-time sensors and feedback loops that detect deviations instantly. If a machine drifts from its programmed path, the system can automatically adjust, eliminating errors before defective products are made. This capability can reduce downtime, prevent material wastage, and avoid expensive rework, ensuring smoother production flows and higher overall equipment effectiveness (OEE) in industrial environments.

Boosting Throughput with High-Speed Motion Control

Speed is a crucial factor in industrial efficiency, but it must not come at the expense of accuracy. Precision motion solutions can enable high-speed operations without compromising performance. Here’s how precision motion products can help boost throughput with high-speed motion control:

Optimized Acceleration/Deceleration

Precision motion systems use advanced algorithms to control acceleration and deceleration, minimizing mechanical stress on components. This can help reduce vibration, extend equipment lifespan, and prevent premature failures, all while sustaining high operational speeds for maximum throughput without sacrificing performance or reliability.

Synchronized Multi-Axis Movements

In tasks like 3D printing and automated packaging, synchronized multi-axis control can ensure precise, simultaneous movements. This can eliminate bottlenecks, improve cycle times, and maintain accuracy in intricate operations, boosting overall efficiency and enabling seamless execution of high-precision industrial processes.

Enhancing Worker Safety

Precision motion products can contribute to safer work environments by reducing the likelihood of mechanical failures or erratic movements. Automated systems with reliable motion control can minimize human interaction with hazardous machinery through the following:

Predictable Operation

Precision motion systems can deliver highly repeatable movements, eliminating erratic machine behavior that poses safety risks. By maintaining controlled, programmed motion paths, these systems can minimize surprises in automated processes. This reliability ensures workers can confidently operate nearby, reducing accidents and fostering a safer industrial environment without compromising productivity.

Fail-Safe Mechanisms

Modern motion control systems can incorporate redundant sensors, torque monitoring, and instant emergency-stop functions. These safeguards can detect anomalies like obstructions or overloads, triggering immediate shutdowns before hazards escalate. Such proactive protection can prevent equipment damage and injuries, ensuring compliance with stringent industrial safety standards while maintaining operational continuity through intelligent risk mitigation.

Future Trends in Precision Motion Technology

As industries evolve, so do the demands for smarter, more efficient motion control solutions. Some emerging trends include:

IoT Integration

Precision motion systems with IoT connectivity enable continuous performance tracking through embedded sensors. These smart systems can predict component wear before failure by analyzing real-time data on vibration, temperature, and load conditions. This proactive approach can help minimize unplanned downtime while optimizing maintenance schedules for maximum operational uptime and cost efficiency.

AI-Driven Optimization

Advanced AI algorithms process historical operational data to dynamically optimize motion trajectories. These self-learning systems can automatically adjust acceleration profiles and movement sequences to reduce cycle times while maintaining precision. The result is adaptive, energy-efficient performance that continuously improves throughput without manual reprogramming, pushing production capabilities to new levels of efficiency.

Conclusion

Precision motion products are pivotal in enhancing operational efficiency across industrial settings. By keeping the information mentioned above in mind, these systems can provide a competitive edge to manufacturers and automation-driven industries. Investing in high-performance motion solutions, such as those offered by leading providers, ensures long-term productivity and cost savings. As technology advances, the impact of precision motion control will only grow, further revolutionizing industrial operations.

Image Sources